Ratul Das, of power and desalination company ACWA Power, gave a keynote at IWA’s Leading Edge Technologies conference earlier this year. Here he shares insights on progress towards zero emission desalination.

Freshwater scarcity – one of the biggest challenges of our time – continues to expand across different regions. This issue is escalated further by the continuous growth of population in inherently water stressed regions.

The Middle East is one of the most arid regions in the world, with a high risk of freshwater stress in the coming decades. Given the region’s abundant access to seawater, a reliance on desalination technologies has become critical to fulfilling the freshwater needs of its population and economy. Of these desalination technologies, the most widely used is membrane-based seawater reverse osmosis (SWRO), as it is considered one of the most efficient methods of desalination and has a low footprint.

Based on the separation of water and inorganic salt solute from seawater through a semi-permeable membrane, SWRO uses energy to counter the osmotic gradient of seawater to produce low salinity permeate and concentrated brine. Because of rapid industrial and population growth, reliance on SWRO is increasing. As a result, the optimisation of existing SWRO plants, along with the design of new, efficient plants, is of critical importance.

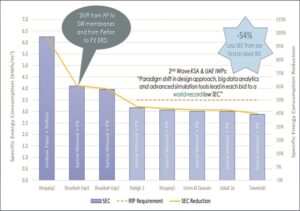

The SWRO process has undergone several enhancements over the past decade, but it remains an energy and chemically intensive process that intensifies environmental stress. To address this, ACWA Power has pioneered a paradigm shift in the design of large-scale desalination plants by making energy needs central to all its design work and by applying a new design approach to desalination plants based on knowledge from its other core businesses.

“R&D is aimed at optimising efficiency to produce desalinated water, reliably and responsibly, at low cost”

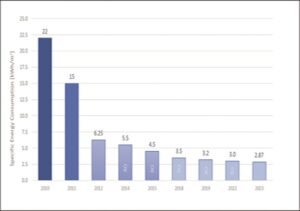

In the past decade alone, we’ve reduced energy consumption from 22 kWh per cubic metre to less than three – almost a 90% cut in power used by our plants. That is not only good for our bottom line, but also for the planet.

ACWA Power has been a champion of the reduction of specific energy consumption (SEC) from the reverse osmosis of seawater. Technological innovation has been part of our DNA from the beginning, and it continues to be integral to the way we operate, and key to our success. Our R&D is aimed at optimising efficiency to produce desalinated water, reliably and responsibly, at low cost.

The pressing demand to squeeze energy consumption to its near theoretical level has prompted research primarily focusing on improving the energy efficiency of the process. The use of novel materials to develop next generation desalination membranes with ultra high water permeability and high water–solute selectivity has been explored thoroughly. Yet, despite substantial research efforts towards the development of highly efficient membranes, the resulting reduction in energy consumption has been minimal. This calls for a paradigm shift in the current approach to desalination research towards rational system design, as well as the optimisation of process operations.

Pretreatment efficiencies

For a SWRO plant to operate to its full, long-term potential and consistently produce optimal water quality, it is critical to have an effective pretreatment system. Effective pretreatment increases the quality of the feed seawater to the RO membranes by minimising its fouling potential, thereby minimising damage to the RO membrane downstream, maximising the lifetime of the RO membrane and reducing energy consumption.

Biofouling prevention

Biofouling is a pervasive problem in the SWRO process. We are working on several fronts to tackle this, including testing of newer pretreatment technologies, such as ceramic and graphene-based ultrafiltration membranes, testing advanced filtration media, and even developing newer methods to test water quality that are more robust than the current status quo.

The accumulation of unwanted material on the membrane surface, collectively called fouling, is key to the improvement of RO desalination. Fouling includes deposition of inorganic minerals, accumulation of particulate matter, and biofouling, which refers to biofilm formation resulting from deposition of organic matter and microbial deposition and growth. Layers of fouling and biofouling of a few micrometres thick are enough to induce increased energy requirements for water production, decreased membrane efficiency, and early membrane failure.

the seawater desalination process

Reducing scaling

The deposition of inorganic minerals or scaling occurs when the concentration of rejected salts along the RO membrane exceeds its solubility limit. To mitigate scaling problems, the addition of antiscalants during pretreatment of the feed water is the most

cost-effective and convenient method. Antiscalants are chemicals that inhibit the formation of minerals through chelation, dispersion, and/or by blocking crystal growth sites.

Although antiscalants mitigate inorganic fouling, they can increase the potential of biofouling, which is regarded as the most difficult fouling problem to deal with. Depending on their chemical components, antiscalants can function as phosphorus and/or carbon sources for microbial growth.

Together with our partners at King Abdullah University of Science and Technology (KAUST), Saudi Arabia, we have developed a method that allows for a rational selection of antiscalants based on assessing their bacterial growth potential and chemical structure using nuclear magnetic resonance (NMR) spectroscopy.

Working smarter

The industry also requires better quality and new types of sensors to enable more data to be derived from plants, and tools to be developed to use this data in a smart way. We are looking at advances in artificial intelligence (AI) to improve sensing technology within a package that allows us to move to predictive analytics. This is very much in line with the direction of our general research portfolio, enabling us to develop a holistic approach for a monitoring system that uses the latest technology to help us further optimise plant performance.

We have developed a model to use an artificial neural network-based algorithm to optimise the chemical consumption of coagulants. This is used to predict the Silt Density Index (SDI) of filtered seawater based on the coagulant dosing rate. The developed algorithm resulted in the reduction of coagulant consumption by 11.7%, reducing the operational cost of the desalination plant.

seawater reverse osmosis process

Automated performance tracking

We used desalination plant operational data to develop an automated membrane performance tracking and diagnostics system. This system is established with data pipelines from more than 20 seawater desalination plants, with a total production capacity more than 5 Mm3/d. The system can provide valuable insights to the operators by supplying important information such as forecasting the timeline for the next cleaning in place (CIP), and detection of the root cause of membrane performance decline. These insights enable preventative and corrective actions to be taken to optimise the SWRO plant’s day-to-day operations and further reduce operational costs.

“we’ve reduced energy consumption from 22 kWh per cubic metre to less than three”

Performance model

A SWRO system consists of different components, such as pumps, membranes, valves, and energy recovery devices, and while it is simple for process designers to understand the performance of these components individually, the performance of an entire SWRO system can be complex and counterintuitive.

We have developed a performance model for reverse osmosis (PMRO) that is capable of monitoring, optimising, and designing an entire SWRO system, starting from the seawater intake through to the post-treatment stage, while meeting final water quality requirements.

PMRO has the capability of predicting plant performance in real time and finding the best efficiency operating points to minimise SEC and reduce operational costs. This is the first programme in the public domain to treat an SWRO process as a complete, coupled system, and aims to meet the needs of all involved in the optimisation process of a SWRO plant.

Software alone, however, won’t be enough. We need a concerted effort to change the way we monitor and measure, combined with smarter tools and the utilisation of collective intelligence – a mix of artificial and human intelligence – to bring about the efficiencies the sector needs.

Disruptive desalination

We’ve recently partnered with a start-up in Europe to develop a new disruptive desalination technology. This will bring together many of the benefits that are now being demanded of the industry and is expected to desalinate 42,000 ppm of seawater at a total plant SEC equal to or less than 2.2 kWh/m3. Additionally, it does not require any chemical additives and produces a brine with salinity much lower than in a typical desalination plant. Essentially, the aim is to produce non-toxic, clean, low-salinity brine to be discharged to the sea, with energy consumption reduced again by a third, so reducing our carbon footprint by a further 30%.

In a nutshell, through innovation we continue to accelerate the transition towards zero emission desalination, aimed at delivering the cleanest, most affordable, and energy-efficient freshwater. •

Acknowledgements:

The author would like to extend his profound appreciation to Thomas Altmann, EVP – Innovation and New Technology, the entire innovation team at ACWA Power, and collaborators from King Abdullah University of Science and Technology, Saudi Arabia.

The author: Dr Ratul Das is Executive Manager, Research and Development, at ACWA Power.