By Timothy Fitzgerald*

Hydraulic fracturing, or fracking, as it is commonly known, is a divisive and controversial issue, in large part because of its perceived effects on supplies of fresh water.

Opposing sides even fight over how to spell the word: worried environmentalists always insert a “k” while the oil and gas industry prefers a “c” (“fracing”). By either spelling, the ‘hydraulic’ part of fracturing gives rise to three problems: the access, disposal, and transport of water.

Yet while the politics of fracking grow stale, entrepreneurs are quietly moving beyond conflict to figure out new ways not only to solve these three old problems, but also to create new opportunities.

Fracking is actually a suite of novel hydraulic fracturing techniques along with directional and horizontal drilling. Combined together they enable producers to extract oil and natural gas profitably from geologic formations like shale deposits once considered too poor to sustain commercial drilling. Producers have expanded into new parts of the United States, many that had rarely if ever seen the industry.

Cities and rural areas alike have experienced a drilling boom. Drilling brought more production, first of natural gas, later of oil. But the increased productivity has also brought controversy over environmental implications, and at the forefront of those concerns is water.

As the name suggests, hydraulic fracturing relies on water–specifically a water-based slurry that is injected into the well. At high enough pressure, the water creates small fractures in the surrounding rock. The injected fluid contains grains of sand that prop open these fractures, and allow molecules of natural gas and oil to migrate out of the rock, to the wellbore and then up to the surface.

Some of that injected fluid comes back to the surface after the pressure is released, often over the course of several days or weeks. That water is called flowback. Other water that naturally occurs with the gas and oil deposits may also come to the surface over the course of time while the well produces. That water is called produced water.

We can lump concerns or stylised facts about water and fracking into two categories: quantity and quality. Quantity concerns centre on the notion that, given finite limits to the natural resource, oil and gas interests will buy up all of the water in regions where lots of drilling occurs. That sort of spending spree would endanger other uses–including agricultural, domestic, and environmental.

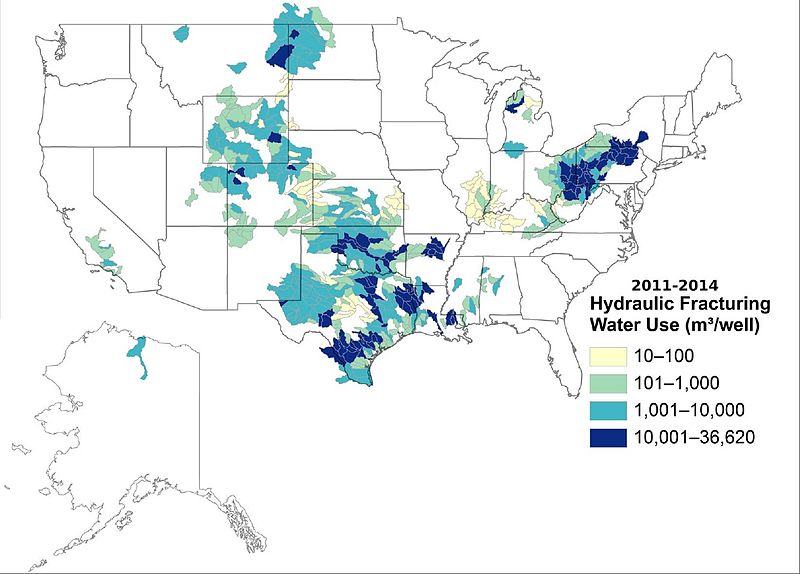

Fracking jobs on wells vary in terms of the size of their thirst–some might use one million gallons of water while others use eight or ten times as much. Where water is scarce, that demand from oil and gas can appear daunting. Yet while a million gallons sounds like a lot to have to drink in a single setting, in most places the incremental demand is quite modest relative to existing uses (those million gallons may produce 600 pounds of beef or 500 gallons of milk).

The other major concern is that fracking will degrade water quality. The most insidious concern is that fluids injected into wells to fracture the gas- and oil-bearing rock will contaminate groundwater. While the costs of proving such contamination are very high, the notion of injecting secret chemicals into the ground has captured the public’s imagination. Halliburton has proved to be an unsympathetic antagonist, yet for all the worry, no cases of subsurface contamination have been definitively proven.

Yet far less attention has been paid to produced water–management of which is actually

a major concern for the industry. Surface spills and leaking pipelines don’t attract headlines, but are far more frequent than subsurface anomalies. The fact that produced water is often extremely saline and can contain other contaminants like heavy metals or naturally-occurring radioactive material only increases the importance of sound handling practices.

Rhetoric aside, modern oil and gas fracking operations raise three related but distinct issues around water: securing it, disposing it, and transporting it, which entrepreneurs must address.

Procurement of large amounts of fresh water is a relatively new problem, because conventional oil and gas production was never all that thirsty. Then, once wells are constructed and production begins, operations must dispose of large volumes of produced water. This is a relatively old problem because water is frequently produced with oil and gas. Last, the logistics of water supply and demand require moving large quantities of water, both in relatively fresh and contaminated states. Water is heavy and expensive to move around, so small gains in transport can have dramatic effects on water usage.

Reducing costs

Entrepreneurs are discovering how to integrate these three issues in new ways, reducing costs, time, and environmental risks.

Procurement often depends on transport. For example, in western North Dakota where the Bakken shale has proven to be an important source of shale oil, a producer might pay US$0.10 a barrel (42 gallons) for water at the wellhead. But depending on distance between source and place of use, transport expenses run much higher, and the delivered cost of 1 million barrels could run to as much as US$1 million.

Procurement issues are simplest in places where water is privately owned and many sellers and buyers can form a marketplace. Texas is the leading example, where private landowners can pump and sell water, and firms broker water between owners and oil and gas producers.

Disposal typically uses injection wells. Hyper-saline brine that was once dumped into surface waters is now injected deep underground, far from potable supplies. While eliminating discharge of highly saline water into surface water improves environmental outcomes, it is not without impacts. Large-volume injection has been linked to induced seismicity in Oklahoma and Ohio, where more earthquakes have been cited as an unintended consequence of fracking. Fracking itself does not cause the earthquakes; the risk comes from injecting large volumes of wastewater along unmapped faults, long after the fact.

But from these problems, opportunity has arisen. Rather than procure and transport water expensively from a distant source, only to then at further cost dispose of produced water somewhere else, fracking operations are finding ways to link supply and demand at the same location and closing the loop in a marketplace of water.

At that point, transport issues then centre around mundane issues associated with moving large volumes of water. Producers increasingly rely on temporary infrastructure in the form of above-ground pipelines rather than tanker trucks. Not only does this reduce truck traffic, a major source of aggravation for local residents, but it also provides operational benefits, bringing down the cost and price to the consumer.

From a single source facility, temporary pipelines can provide real- time servicing of fracking jobs and flowback water. When developers move on to new sites, the pipelines can go with them.

The opportunity for inexpensive and abundant energy supplies is one of the benefits of fracking. New issues for water sourcing, disposal, and transport are being rapidly overcome by innovators using the forces of supply and demand to reallocate water to new uses.