Growing water scarcity, stricter regulations, and rising environmental concerns are driving the global demand for sustainable water treatment solutions. Whether municipal wastewater treatment, seawater desalination, or industrial wastewater treatment – precise mechanical filtration plays a crucial role in ensuring resource efficiency and environmental stewardship. Filter elements made of metal wire mesh provide a versatile, reliable solution, meeting complex challenges with precision and durability.

High-performance filtration with metal wire mesh

Filter elements of wire mesh stand out for their reliability even in extreme operating conditions. Offering high flow rates and substantial dirt-holding capacity, they enhance process efficiency, stability and safety. With their ability to filter particles down to a size of 5 µm, including microplastics, they reduce the need for additional chemical treatments – saving energy, lowering operational costs and minimising environmental impact. Their decreased blocking tendency, in comparison to alternative filter media – such as fleece – and their optimised regenerability enable plant operators to extend cleaning intervals and reduce the burden involved in mechanical and chemical cleaning.

Customisability and predictive simulation for optimised solutions

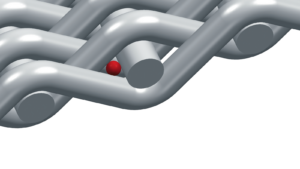

By selecting from various materials, weave types and the suitable support and drainage layers, design and filtration properties can be precisely tailored to a wide range of applications. In addition, innovative 3D mesh structures enable highly corrosion- and temperature-resistant filter meshes with pore sizes smaller than 40 μm.

Advanced simulation tools enable the precise modeling of fluid dynamics and filtration performance before the implementation, ensuring the system meets operational needs without costly trial-and-error adjustments.

Ultra-fine filtration with MINIMESH® S filter mesh

With metal wire mesh, a distinction is made between open square or rectangular meshes and optically closed dutch weave types. In various water treatment systems in which particles down to the micrometre range from 5 μm must be filtered out precisely and economically, the use of MINIMESH® S filter cloths as a filter layer has proven its worth. In plain dutch weaves, the warp or weft wires are woven so close together that they are called zero aperture meshes. In contrast to classic mesh sizes, these meshes have what are known as geometric pore sizes, defined by the diameter of a sphere that can just pass through the filter cloth. Both the geometric pore size and the permeability can be precisely calculated so that the filtration behaviour can be simulated before production.

MINIMESH® RPD HIFLO-S for water treatment

Especially in ultra-fine filtration, innovative 3D filter media also open completely new possibilities: Thanks to their three-dimensional pore geometry, their dirt-holding capacity and flow rate are maintained for significantly longer than with conventional filter media. In addition, special materials can also be woven in the small pore spectrum, making highly corrosion and temperature-resistant filter meshes available in the ultra-fine range for the first time.

Case studies: proven effectiveness across the globe

Haver & Boecker’s MINIMESH® RPD HIFLO-S series has been successfully deployed in a variety of applications, demonstrating its versatility and reliability:

- In Namibia, the jointly funded HygO project is being supported by modern hydrogen technology. The aim is to develop a self-sufficient energy system in the form of so-called microgrids. The HygO microgrid features an additional circuit for biological-mechanical water treatment, in which intermediate MINIMESH® RPD HIFLO 5-S filter cartridges retain particles from 5 µm.

- In Norway, the start-up renasys demonstrates how innovative microscreen systems can significantly reduce the energy consumption of wastewater treatment plants. By using MINIMESH® RPD HIFLO 5-S filters, up to 99% of the dirt particles are removed before the actual clarification process.

- For seawater desalination in drought regions, pre-filtration with MINIMESH® S filter cloths extends the lifespan of reverse osmosis (RO) membranes by capturing fine particles, thereby improving overall system efficiency and cutting operating costs.

Adapting to the future of water management

As water systems evolve to incorporate smarter technologies and more sustainable practices, the role of advanced filtration solutions will only grow. Wire mesh filters align with circular economy principles, offering recyclable materials, reduced chemical usage, and lower energy demands. Their durability minimizes waste, making them a sustainable choice for modern water management. For a deeper dive into the technologies and their applications, download our white paper and explore how Haver & Boecker solutions are shaping the future of water treatment.

As water systems evolve to incorporate smarter technologies and more sustainable practices, the role of advanced filtration solutions will only grow. Wire mesh filters align with circular economy principles, offering recyclable materials, reduced chemical usage, and lower energy demands. Their durability minimizes waste, making them a sustainable choice for modern water management. For a deeper dive into the technologies and their applications, download our white paper and explore how Haver & Boecker solutions are shaping the future of water treatment.

HAVER & BOECKER OHG WIRE WEAVING DIVISION Business Development

Ennigerloher Str. 64 59302 Oelde Germany

Tel.: +49 (0)25 22 30-433 bd@haverboecker.com www.haverboecker.com