In India, a research scientist and his team are manipulating invisible matter in ways that could quietly disrupt the global water purification industry

By James Workman

Like water, the 33rd element on the periodic table lacks colour, consistency, odour and taste. Yet in places where it seeps into water supplies, arsenic can kill.

It is a naturally occurring poison that affects 137 million people across 70 countries. At high concentrations it inhibits human IQ, cripples immunity, damages nerves, and causes skin, lung, heart and intestinal disease.

Despite this, until now there has been no affordable solution available to water laced with arsenic. But a team under the guidance of Professor Thalappil Pradeep of the Indian Institute of Technology, Madras, has developed a new treatment based on nanotechonology, which purifies water, removes arsenic, and does this at a price affordable for the poorest communities.

“While India and the world are marching ahead, a large majority do not have water, so better and better solutions are needed, and they must be affordable,” says Pradeep. “Today we can deliver arsenic-free drinking water at a cost of US$0.0007 per litre or less.”

An official first noticed the effects of Pradeep’s innovation in West Bengal when he was randomly testing samples and monitoring wells for contaminants. The World Health Organisation considers 0.01 mg arsenic per litre safe. Here, as pesticide pollution combined with naturally occurring arsenic, concentrations had risen to 3 mg per litre. Yet for two wells the usual level of contaminants, including arsenic, had vanished without trace.

These wells formed part of a small-scale pilot which had been organised by Pradeep, a chemist who specialises in sub-molecular tools known as ‘nano’ technology.

Pradeep had long navigated his way around an atomic force microscope, and had used it to examine reactions taking place 100,000 times smaller than the width of a human hair. But in recent years his laboratory,and his muse, was water in human communities. “Water to me is a problem of materials,” says Pradeep. “Availability of affordable, advanced, functional and sustainable materials will decide access to clean water. And in advanced materials, the most exciting are things of nanoscale dimensions.They include nanopores, nanocages, nanochannels and many more. They encompass all aspects of water-sensing, scavenging and understanding phenomena.”

Scaling down for global outcomes

The International System of Units describes one nanometre as one-billionth of a metre. That’s 100,000 times thinner than a sheet of paper, a little more than half the size of one strand of human DNA, and the distance your thumbnail grows each second.

In the realm of nanotechnology applied to water treatment, a nanometre is three times the size of a gold or silver atom. And that’s where matters get interesting.

At the nano scale, gold no longer appears yellow; it’s apparently closer to red or purple. While perhaps less pretty, atomic gold becomes immensely practical, and its properties can be fine-tuned for an outcome. “We are essentially manipulating ingredients at the atomic or cellular structure of life,” says Pedro Alvarez of Rice University.

Starting a generation ago, access to high-powered tools enabled researchers to see, work with, tune, and fabricate stuff at the nanoscale. Most applications are aimed at high-end markets, like smartphones or biotech. Nanoparticles can be used to image, find, target and treat tumours and nanotech can help cut the cost and time of gene sequencing. Yet engineering nanotechnology to absorb and break down contaminants remains one of the youngest and least funded fields of research.

For water treatment, proponents claim nanotechnology has both huge potential and high hurdles. The barrier to adoption by water professionals comes not so much from a shortage of capital or scientific know-how, but from the lack of public understanding and acceptance.

Much like with genetically modified organisms–another manipulation of matter that low-income brackets might consume–society’s ignorance elevates fears about unknown consequences. What if nanoparticles break down in the aquatic environment? What if unforeseen problems arise?

“We still don’t see too much nanotechnology in practice due to social and environmental concerns, and a negative perception,” says Ralf Kagei, who runs the particle lab at Eawag, Swtizerland. Perhaps what gives Pradeep’s team room to experiment is that in parts of India, everyone knows invisible, deadly particles in the aquatic environment are already causing horrific problems. A child or mother who faces naturally occurring contamination is more likely to welcome the introduction of another invisible ally that will, at last, help humankind fight back. They include nanopores, nanocages, nanochannels and many more. They encompass all aspects of water-sensing, scavenging and understanding phenomena.”

Pradeep has been immersed in the field of nanotechnology for many years, publishing 330 scientific papers on fascinating but obscure aspects of his research

Pradeep has been immersed in the field of nanotechnology for many years, publishing 330 scientific papers on fascinating but obscure aspects of his research. Yet by 2002 he had grown haunted by the prospect of poor Indian families asking: “Has all your science solved any of our real problems?”

Water and sanitation were the most obvious and urgent crises. So over the next five years he set out with a small team to research, develop and market what would become the world’s first nanotechnology-based domestic water purifier.

Up to that point, most water purifiers were energy- intensive and nature-polluting devices aimed at the small segment of consumers who could afford them. These ranged from humming reverse osmosis plants near big cities to countertop pitchers that occupied the top shelf of refrigerators in wealthy families. Brita’s filters, in the mid-range, cost US$72 per 1,000 litres, but in some tests removed less than 15 percent of lead and arsenic (while increasing aluminium).

By contrast, Pradeep’s model looks like a modified plastic field bucket.

He designed it with no plugs, no wires and no disposable parts. Yet he made sure that its design would be able to remove everything that universally threatens human health: suspended particles, pesticides, microbes, metals and anions. The magical transformation, from poisoned slurry into fresh potable water, would have to take place passively, at room temperature, among uneducated families.

And it would cost no more than US$16.

Overcoming the sceptics

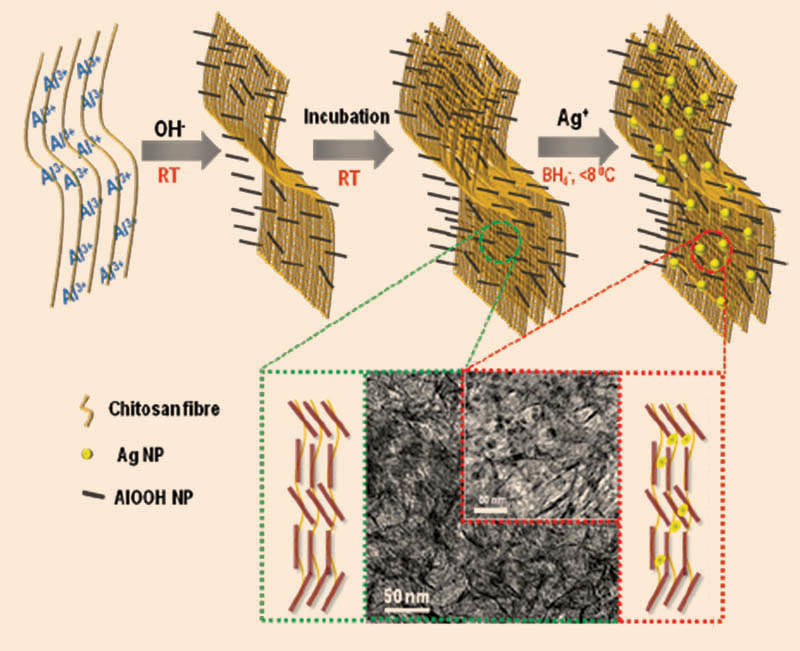

To pull off such alchemy, Pradeep’s team manipulated silver nanoparticles, impregnated within a protective ‘cage’ built out of nanomaterials like aluminium and the chitin from crustacean shells. The resulting reaction breaks down the halocarbons of pesticides and other microbial contaminants into harmless metal halides and amorphous carbon.

“Today, we can deliver arsenic-free drinking water at a cost of US$0.0007 per litre or less”

After much iteration, through trial and error, a version finally worked. Pradeep believes his breakthrough innovation, and those that followed, could greatly improve daily life in the developing world. He speaks of his work in a calm, patient, quiet voice that doesn’t quite conceal the inner pride in his accomplishments and their place in history. He has put his filter on a par with reverse osmosis. What was frustrating is how, for a long time, no one else seemed to agree.

“I remember telling industrialists that this would be a big thing and to invest in it,” recalls Pradeep in frustration, as one investor after another declined to bring it to market. “Obviously, people were sceptical.”

Pradeep’s challenge would sound familiar to anyone marketing clean tech innovations, especially for water, as those who benefit most have the least amount of disposable income. But there’s also another complication: nanotechnology scares those who don’t understand, or feel intimidated by it.

Even a decade after its first commercialisation, the frontiers of nanotechnology remain foreign to many if not most water professionals. Traditional engineers and chemists tend to respond to Pradeep’s ambitions with one of two mutually-exclusive reactions: “It’s already been done” or “It can’t reliably be done.”

Last October, when Pradeep presented his latest work on clean water and public health, the initial response among water professionals was a collective yawn. “Gold particles have been used in water throughout history” shrugged one observer. Historians have documented how Alexander the Great drank water from a silver goblet to harness silver’s microbe-killing ability. Early colonial settlers dropped silver coins into water barrels to suppress algae.

These audiences are missing the point, and the excitement that goes with it. What Pradeep’s team has done with silver is six orders of magnitude smaller, and at the same time larger in terms of social impact. It’s as if he shattered that silver coin into a million bits, and flattened each one into foil with an aggregate surface area millions of times higher than the coin, making it more conductive and a better catalyst. Then, building back up, Pradeep restructures each foil in a protective cage–much like a catalytic converter in a car engine reduces toxicity from exhaust fumes–so that his filter can absorb and transform huge quantities of contaminants, cleaning toxic water for poor families.

There’s an obvious warm-hearted social equity aspect to this approach that would make Ghandi proud. But there’s a hard-nosed economic and political angle he’d admire as well. Silver is expensive, so getting it down to a scale of 25 parts per million opens a water treatment market to those without reliable taps who subsist on less than US$2 per day.

How nanotechnology works?

As water passes through the filter, the silver nanoparticles are oxidised and get released in water continuously in permissible limits (below 100 ppb), which kills bacteria and viruses.

Chitosan fibres, shown as wavy objects in the figure below, combine with aluminium oxyhydroxide nanosheets made in-situ, to form a claylike “cages” that can protect embedded silver nanoparticles. The powders produced this way, when expanded a million times under a microscope, we can see embedded silver nanoparticles in the cages made of nanosheets, shown schematically above. In such cages, water gets in and dissolved silver ions can get out, but the particles themselves are trapped. Also, no particulates get into the nanoscale cages, protecting the nanoparticles from fouling.

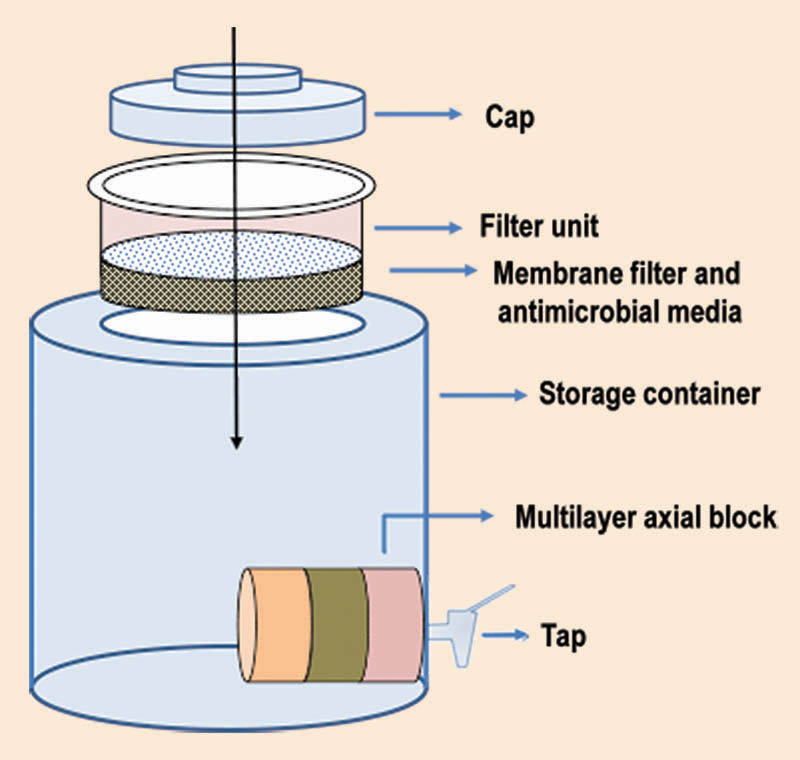

A small prototype of the water filter is shown here. The antimicrobial material is housed at the top roof of the vessel where the untreated water is passed to kill bacteria and viruses.

A multi-layer block of composite to remove specific contaminant is situated behind the water tap. The size of the vessel may vary from a few hundred to a thousand litres.

The membrane filter at the top kills bacteria and viruses and the axial block at the bottom can be custom fitted with nanocomposite material for removal of toxic contaminants from the water.

This technology has received West Bengal government’s support for field trials in the district of Mursidabad and Nodia. With the funding available around 100 units with water filters of 600 litire capacity have already been installed in the district of Mursidabad by InnoNanao Research, a start-up founded by IIT Madras team.

Scaling up

This leads to a second negative reaction: even if it works, such technology surely can’t be replicated. In fact, nanotech for water treatment could scale up faster precisely because it require less infrastructure, less material and less energy. “There’s a perception that nanotechnology is too expensive,” says Pedro Alvarez of Rice University. “But the truth is just the opposite. Like 3D printing, the mobile function means it has incredible capacity for point of use, decentralised and distributed applications at the source.”

That theory is fine. But funding agencies remain unsure about its implications in practice. Friendly critics, like James Smith, Professor of Environmental and Civil Engineering at the University of Virginia, worry the filter might prove too complex and sophisticated to be easily manufactured or maintained in developing countries by resource-poor families.

That overlooked demographic is known as ‘the bottom of the pyramid’. While hundreds of millions of people still lack reliable clean water, the missing link has been whether provision is durable, accessible and affordable. Through nanotechnology, Pradeep lowers barriers to entry on all three counts.

For starters, his team has now eliminated the need for materials to be reactivated in the field; no heating and boiling is needed at periodic intervals. Scaling up, the State Government of West Bengal has, over the last 18 months, ordered the installation of 2,000 supersized filtration units. Each one supports the water needs of 300 people, covering more than half a million at the heart of the arsenic belt. So much for replicability concerns.

Now consider that the older commercialised unit that Pradeep patented, licensed to an Indian firm, and designed for pesticides, has sold roughly 1.5 million filter cartridges. At a US$16 retail price, that US$24 million zmarket niche may still seem relatively small, with possibly thin profit margins, and is thus unlikely to interest incumbent high- end brands from Europe or North America. After all, given the costs, why bother competing?

Yet that’s the classic definition of disruptive technology. Once innovation like Pradeep’s can build up market share at the bottom of the pyramid, nano-purification has nowhere to go but upscale, offering higher performance to ever more profitable segments at lower costs until, bit by bit, the roster of comfortably established competitors may well be driven from the market.

There’s a reason such disruption to water treatment has emerged not from a Silicon Valley incubator or a European university lab, but rather in the troubled wells of the most water impoverished societies on Earth. Here, low-income demography, geographic concentrations and unrestricted policy form the ideal petri dish for Pradeep to push new boundaries and apply nanotechnology to water.

True, India may have its own developmental challenges, he says drily, but “it is not a country of snake charmers any more”. It is launching satellites, and has just sent a mission to Mars. More importantly, he notes, is how ‘haves and have nots’ co-exist side by side. They share the same rivers and aquifers but are exposed to very different levels of natural risks from these sources.

The US National Nanotechnology Initiative is finally waking up to this potential, highlighting how a large surface area of nanostructured membranes and materials makes them ideal candidates for water treatment and desalination. But Pradeep’s team is already off and running.

Pradeep’s unit continues to extend the reach of nanotechnology tools, testing performance under diverse water-quality conditions

Right now, the team’s challenge remains translating R&D into commercial production with local partners. Pradeep’s unit continues to extend the reach of nanotechnology tools, testing performance under diverse water-quality conditions.

“So far we have been able to tackle all the field conditions,” he says, adding that the more they understand, the further the realm of marketing activity expands. He sees “infinite possibilities” around “sensing, remote monitoring, service and other areas of water purification, involving other materials, membranes and biology”.

Pradeep knows the risks of trying to do too much, too soon, and overextending. “Our hands are very full,” he concedes. “Yet, the situation forces us to do more as no effort is enough when it comes to water.”